Touchscreens are getting more and more important for modern media. The most striking advantage of this technology is the combination of intuitive in- and out-put devices, which allow the user to directly interact with the system and vice-versa. But how does such a screen work, which types are available, and why do certain type of touchscreens react to fingers, but not to a normal pen? These questions we will answer in this week’s featured question.

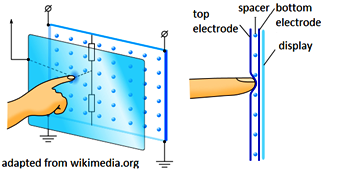

One of the first touchscreen technologies (that is still in use nowadays) is the so-called resistive screen. This specific screen type is composed of two conductive, relatively transparent layers (usually indium-tin-oxide (ITO)), which are held separated at a small distance by spacer dots. To the bottom layer, a small voltage is alternatingly applied in x- and y-direction, while the top layer connects to the second half of the circuit. They are capped by a stiff, but bendable layer and directly sit on the actual display. Touching the screen with a little bit of pressure bends the conductive layer on top and closes the circuit. The resulting currents along the x- and y-circuits can be measured and provide information about where the circuits are closed. The idea is that the longer the current path , the higher becomes the electrical resistance. This technology is still commonly found in cheaper devices and in devices meant to be operated with gloves and can yield high accuracy. However, due to the mechanical deformation the screen has a finite lifetime.

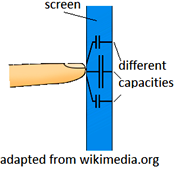

The second, and probably most common, technology is used in “projected capacitive screens”. Those screens are composed of two grids, rotated at 90° to each other, of very fine conductive wires (usually ITO deposited on glass) with spacers in between. In contrast to the resistive screens, they do not form a continuous layer. Instead, the ITO grids create a large amount of crossings, which act like little capacitors whose capacity changes whenever a conductive or dielectric object (like a finger) approaches the grid. A digital controller measures now the capacity of all grid points one by one and if a certain deviation from the saved standard value is reached, a touch is registered. This technology allows multi-touch applications since all grid-points are measured separately and the image quality is enhanced due to the lower amount of ITO between the user’s eye and the actual display. However, these touchscreens need specific materials to be able to detect a signal and barely work with thick gloves or normal pens due to the fact that the capacity does not change if a standard insulator (like plastic) is brought close to it.

There are far more types of touchscreens based on, e.g. infrared light, inductive coils, sound and the piezoelectric effect. However, the two types, mentioned here, are the most commonly found ones nowadays. In the future, there might exist even more sophisticated types of human-interface-devices (HIDs), but at the current time, touchscreens still are one of the most successful HIDs and were able to widely repress the simple push-buttons.

–Kai Litzius

Further reading: